Steel pipe production technology development began with the rise of the bicycle manufacturing, oil development in the early 19th century, two world wars ships, boilers, aircraft manufacturing, after the second world war thermal power boiler manufacturing, chemical industry and the development of oil and gas drilling and transportation, effectively driving the steel pipe industry in the development of varieties, yield and quality.Generally, steel tubes are divided into seamless steel tubes and welded steel tubes according to the production method. This time, we'll talke about welding steel tubes.

Welded steel tubes are welded steel tubes with joints. The production of welded steel tubes is a process in which the blanks (steel plates and strips) are bent and rolled into tubes of required cross-sectional shape and size by various forming methods, and then welded by different welding methods to obtain steel tubes.Compared with seamless steel tube, welded pipe has the characteristics of high product precision, especially the precision of wall thickness, simple main equipment, small floor space, continuous operation in production, flexible production, wide product range of the unit and so on.

Welding tubes, which are divided from production technology, are divided into: Spirally Submerged Arc Welding;LongitudinallySubmerged Arc Welding;ERW Electric Resistance Welding.

The production process of spiral steel pipe is roughly as follows

The spiral steel tube raw material namely strip steel coil, welding wire, flux.

● Before forming the strip after leveling, cutting edge, planing edge, surface cleaning transport and bending edge treatment.

● The weld clearance control device is adopted to ensure that the weld clearance meets the welding requirements, and the pipe diameter, the amount of wrong side and the weld clearance are strictly controlled.

● After being cut into a single steel tube, three steel tubes of each batch should be subjected to a strict first inspection system to check the mechanical properties of the weld, chemical composition, state of dissolution, surface quality of the steel tube and through non-destructive inspection, to ensure that the tube making process is qualified before it can be formally put into production.

LongitudinallySubmerged Arc Welding

LSAW is generally made of steel plate as raw material. After different forming processes, it adopts double-side submerged arc welding and post-welding diameter expanding to form welded pipe.The main equipment is milling machine, pre-bending machine, forming machine, pre-welding machine, expanding machine and so on.

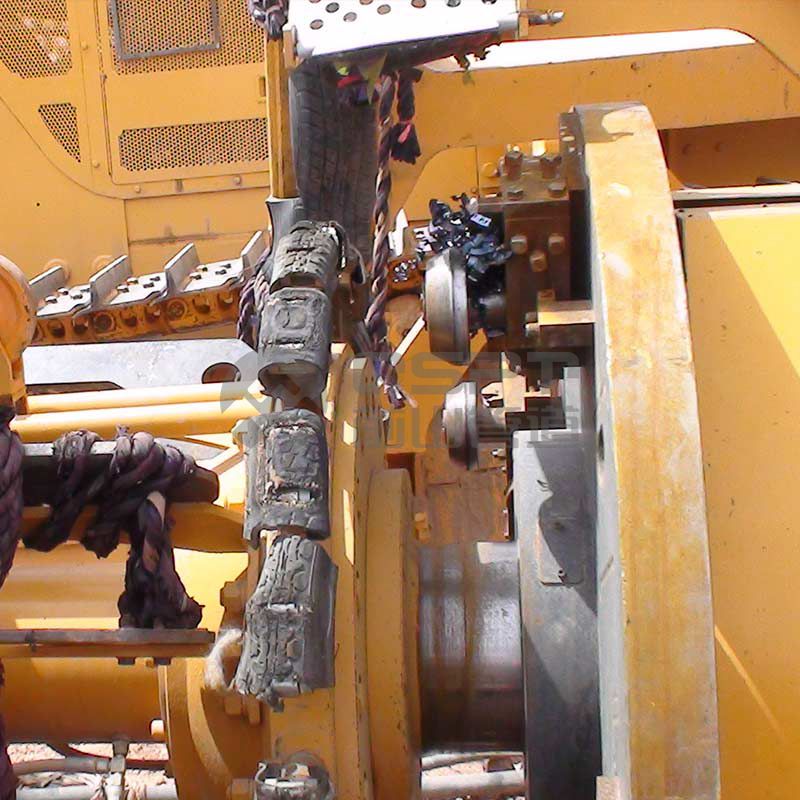

ERW Electric Resistance Welding is produced by heating and melting the edge of hot rolled coil plate by using the skin effect and proximity effect of high frequency current after being formed by the forming machine.

2020-12-10

2020-12-10